Author: Time:2023-02-28

Gaussian light homogenization

microlens array is different from the structure of traditional optical

elements, which makes it have many excellent effects and functions. Common

applications of microlens array include: laser homogenization, Gaussian light

shaping, Gaussian light homogenization, wavefront detection, fiber coupling,

laser cutting, etc. Among them, laser homogenization, Gaussian light shaping

and Gaussian light homogenization are the most common. Because, whether used in

laser processing or lighting, fiber coupling and Gaussian light homogenization

can greatly improve the effect and process controllability. However, there are

many types of microlens arrays on the market, with complex parameters and

different manufacturers. So how to select a suitable microlens array based on

your own laser homogenization requirements? This paper briefly introduces the

homogenization scheme of dual arrays, and the selection of microlens array for

Gaussian light homogenization shaping.

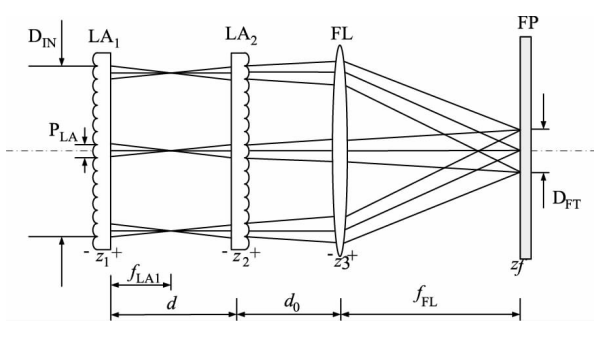

The optical path diagram of

Gaussian light shaping scheme for laser homogenization of double microlens is

as follows:

LA1, LA2, FL and FP are respectively microlens array 1, microlens array

2, focusing lens and imaging focal plane from left to right. It can be seen

from the above figure that the structure of microlens array is flat and convex.

The plane is opposite, and the convex surface is the structure with microlens.

The incident Gaussian laser to be homogenized and shaped is collimated from the

left and then incident into the microlens array. The sub-unit aperture of the

two Gaussian light homogenizing microlens arrays should be consistent and

close. The spacing between microlens arrays is equal to the focal length of

microlens array 1, which is generally slightly larger. The distance between the

microlens array and the focusing lens FL will slightly affect the divergence

angle of the homogenized light spot, but the influence is small, and is

generally ignored in the selection calculation. In practice, this distance can

be adjusted to fine-tune the effect and size of the microlens array. The end is

the effect end of Gaussian light homogenization of microlens array.

The relationship between the

size of the laser homogenization spot of the microlens is as follows: (pLA is the aperture

size of the sub-unit of the lens array)

DFT=pLA·fFL·(fLA1+fLA2-a12)/(fLA1·fLA2)

Under the conditions shown in the upper light path, a12=fLA2, the above

formula can be simplified as follows:

DFT= pLA·fFL/

fLA2

Therefore, according to the formula, the required microlens array

parameter range and target direction can be obtained simply. It is assumed that

the homogenization requirement is to form a 10 * 10mm square spot at 300mm.

Then there is: DFT=10mm, fFL=300mm, and the ratio of

aperture to focal length of microlens array can be calculated by taking the

formula: pLA/fLA2=0.03333. If it is a rectangle, calculate the long and short

sides respectively.

In theory, the smaller the

aperture of the microlens, the better the homogenization effect. However, if

the aperture is too small, there will be diffraction interference, and the

final homogenization effect of hardness is not so good. Therefore, it is

generally recommended that the caliber should be slightly enlarged when

selecting models. The aperture requirement of the microlens is determined, and

the corresponding focal length can be calculated according to this

pLA/fLA2=0.03333, and the acceptable microlens parameter range can be obtained

at the same time.

In the optical path, the main

function of the focusing lens at the end of the microlens is to improve the

homogenization effect and adjust the position and size of the Gaussian light

homogenization, which is not necessary. If the required light spot is far away

or large, it can be removed.

It should be noted that because

the periodic microlens array is selected, there are certain requirements for

the light source itself. If it is a light source with small M2 and high

coherence, the Gaussian light shaping and homogenization effect of microlens

array is not so good. For this light source, it is recommended to use

diffractive shaping homogenizing elements to achieve high homogenization. Of

course, you can also pass light through the scattering plate first and then

incident it to the microlens array homogenizer group, but the effect is not

cost-effective, and is generally not recommended.

In the process of using the

dual-piece microlens array, it is particularly important to align the centers

of the two microlens arrays. This can be adjusted by rotating the lens and

moving it slightly. Due to the area accuracy of the microlens array and the

quality of the light source, the homogenized light spot will have a certain

amount of speckle, which is a normal phenomenon. Due to the weak speckle, the

final use is generally not affected. However, speckle removal requires high

accuracy, costs a lot and is not cost-effective. This is a common phenomenon of

microlens array shaping, both at home and abroad.

Product Navigation : Microlens Array Off axis

link : Sina Blog Alibaba163 Blog

Copyright: Highlight Optics Co., Ltd. Address:4A150 No.1 Trading Plaza, China South City, Longgang District, Shenzhen, China

Phone: 0086 0755 89319011 Email: sales@highlightoptics.com